All our visitors had gone so it was at last time to pull the windlass and fix it. So these are the steps we took

- Make sure that the windlass is electrically isolated. We did this by first making sure that the windlass was switched off, we even went as far as removing the cables between the electrical supply relay and the windlass. This was so that if we needed to pull wires we could do so safely.

- While the windlass is still attached to the boat, make sure that all the components that need to move can move and that nuts and bolts that need to be removed are not locked in place by corrosion. To help with this task use an oil like WD40

- With our windlass the wiring from the boat goes to the motor which is behind a protective cover. To remove this cover we needed to hit it with a hammer to break the seal. Also the cover was over the windlass in such a way that the windlass needed to be tipped forward so that the cover could be removed

- Unattach the electrical connections to the windlass motor making sure that you label them as you go

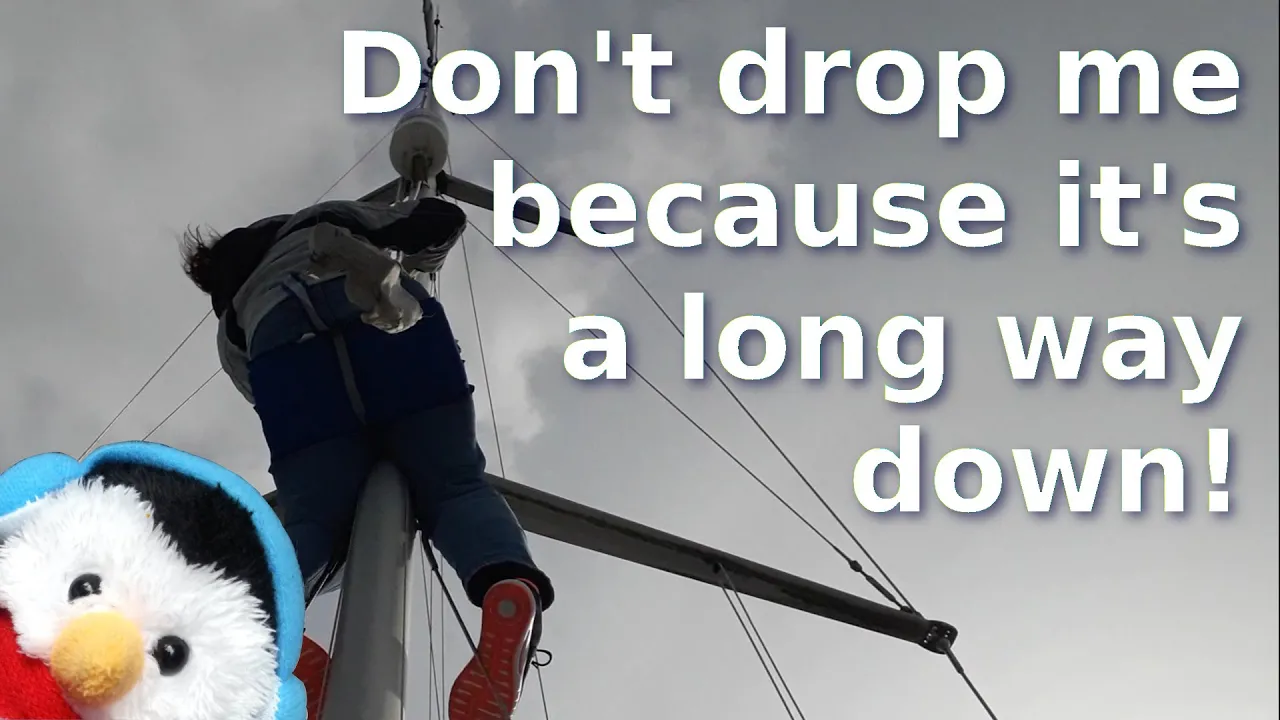

- Pull the windlass, we used various ropes on pulleys so that we could do this

- Once you have the windlass on a work bench our kitchen counter in our case, strip the windlass down as much as you can, this is so that you can clean these components with sand paper and wet and dry.

- With our windlass, the only way to change the oil is to tip it up and let the oil pour out of the fill hole.

- Clean the oil chamber, we poured oil into the chamber and rotated the windlass, this is so that old oil could mix with the new gear oil, by doing this several times we cleaned the old oil out as much as we could

- Pour the new gear oil in and make sure that all the components are rotating smoothly

- Clean all the bearing surfaces

Sorting out the windlass motor

Cleaning the bearing surfaces and changing the oil alone did not solve the issue, so this meant that we had to remove the motor and clean that.

- Remove the motor, we did this while the windlass was in situ. This meant that the main body of the windlass was locked in place and we could revolve the motor by slowly tapping the motor and wiggling it.

- To remove the motor we used penetrating oil on the end with the key way so that the rubber gasket around the shaft could slide over the key

- To remove the cover on the other end we tapped and eventually we managed to remove the case

- Sand the bearing surfaces with dry wet and dry

- Clean between any connections with a cocktail stick

- Mark up the motor so that you know where the screws are as these are internal and you need everything to line up

- When tightening a screw back it out first until you hear a click then tighten the screw

Putting the windlass together again

- Replace all gaskets and seals with new. If you don't have a new gasket then use the next best thing which is butyl tape.

- Lightly sand all the electrical connectors to improve the electrical connectivity of the connections

- If you need and extra insulation around the terminals, use amalgamating tape