When you are on the hard, there is a huge list of jobs that you want to do in the shortest time possible

Prop

The work that needed to be completed on the sail drive was adding the new anode before putting it back together. I tell you, the prop really needed a good clean, there was sand everywhere. Once it was cleaned, Beverley used the Selden grease on the shaft. The other little job that we did while we had the chance was change the oil in the sail drive.

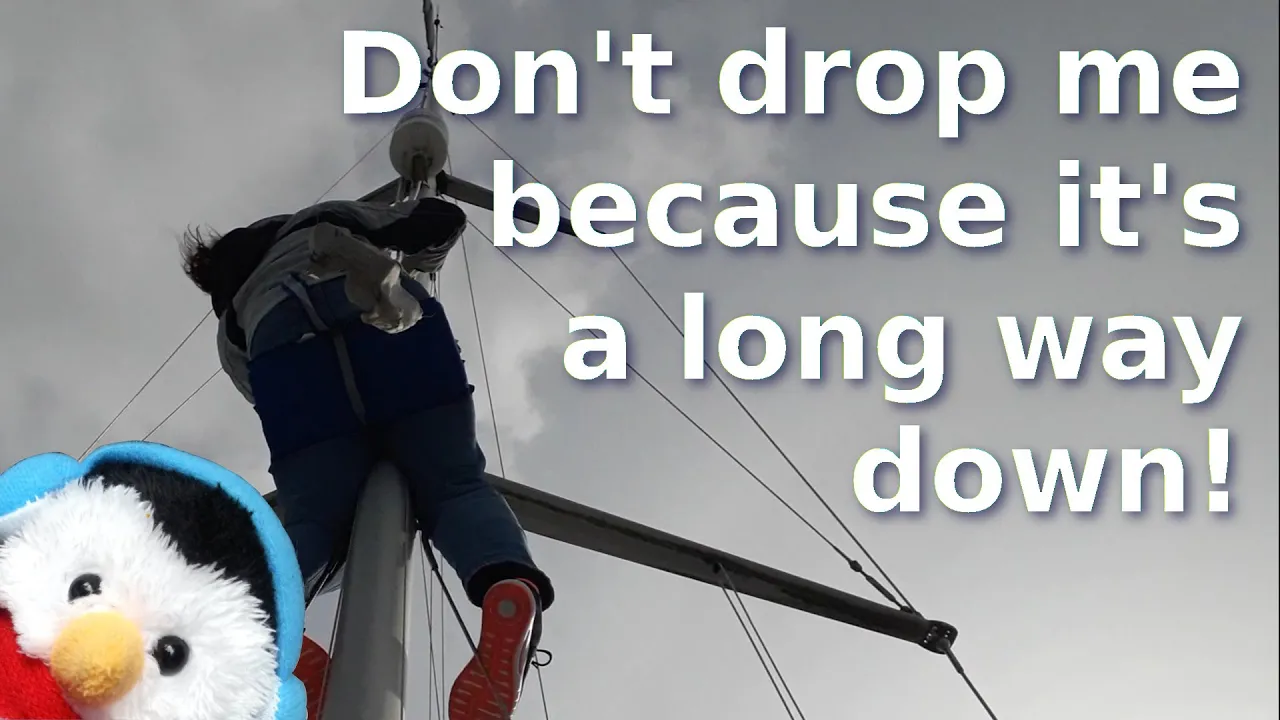

Mast

There was still lots to do on the mast, one of the jobs was to put on a new bracket for the new mast head light and to put the new windex on. Once all the hardware was on it was time to get my crimping tool out of the electrical bag and crimp those terminals. We decided to use plug terminals as these left the least amount of metal exposed. Once we had crimped the terminals, we taped them up and put them under the new bracket so that there was further protection from the elements. While the mast was still down we tested everything with a P3 battery.

Another job was to upgrade the running rigging. Our main halyard was made of wire and rope and the wire section of the halyard had two bulges in and one wire on the outside that had actually snapped, so that had to be replaced. As it had to be replaced we took the opportunity to buy a longer piece of rope as we use the main halyard for all sorts of jobs in addition to hoisting the main sail, plus we bought one that had a great colour, blue in this case. Other ropes that were added was the spinnaker halyard and a spinnaker pole hoist. We choose red and green ropes for this but if I had been thinking clearly, we should of chosen green for the hoist as the sleeve for this comes out on the starboard side, while the spinnaker pole hoist is on the port side, but we have red for the halyard as this was the longer rope and both Beverley and I prefer red to green.

The last job that we did on the mast was put dry lube into the slot, this really helps with the lifting of the sails.

As soon as we were done, the yard pressed us to get the mast on as the guy who was doing our rigging was going on holiday, although Beverley and I had plans to do the sewage, we were quite happy to put the mast on instead, Who wants to do sewage?

This meant that we had to get a whole load of other jobs done like put on all the running rigging that I had washed.

It was really exciting getting the mast on, there was so much happening, new bottle screws, tensioning the mast using a loose gauge and trying to put the main sheet on. We did this about three times before we got it right.

Sewage

When all the other jobs were done, there was no more excuses that we could use, it was time to tackle the sewage systems. This time I got the short end of the stick which meant that I would be the one removing the old sewage pipes in the toilet. Everything was fine, but once I had removed the last of the clamps and I had got the pipe off the toilet the smell was crazy. The pipe was so clogged up with calcium that I had to remove the pipe in sections. I soaked some of the pipe in vinegar and that did remove a lot of the calcium so good to know.

All weekend we worked on the sewage, we had to do the small sewage pipe twice because Beverley broke the seal, there was so much swearing going on during that time. I'm afraid I found it quite funny as Beverley rarely swears. We worked really hard and by the end of the weekend we were ready to go back in the water.

Welcome diversions

While we were in the yard, there was a lot of welcome diversions, like the movement of the yacht next to us, which as soon as it was splashed was replaced by a rather large motor boat. The only problem was that they nicked our power, as soon as our back was turned. I pointed out what they had done and they moved their cable to a location a lot further away. They even put a whole load of credit on our socket, which was very generous as I don't think they used that much. Another diversion was having our meals out in the cockpit and generally chatting to people. They gave us a lot of great advice on how we could get the jobs that we wanted to do done.

Going back in the water

It was Monday and the yard lifted Salty Lass as soon as they started work. While she was in the sling I put anti-foul on the bottom of the keel. While we were suspended in the sling, I reflected on how cruising is so totally different to my previous life which I spent behind a desk in an office, admittedly the office was in my home, but it was still an office

We had to get off Salty Lass, while they were putting her back in the water, but once she was splashed, we went back onboard to find a small drip, so a man came onboard and fixed it in hardly any time at all. Once splashed we went back to our slip. It was great to be back in the water, now we just need to get Salty Lass ship shape.