Every time we come back to Liverpool, we update a little bit more of the yacht. On our way down from Whitehaven, the cover on the wheel had got a little bit tatty, so one sunny afternoon, I got my sewing stuff out and repaired the wheel cover. One job down just 400 more jobs to go.

The lettering for the dingy had arrived while we were gone, so while I sewed Beverley added our dinghies name "Salty Sausage". At last our dinghy is insured, as you need the wording t/t Salty Lass to be insured.

Next up was cleaning the cushions inside the yacht. They were fairly easy to do because somebody at Bavaria had thought about it and had actually put zips in all the right places. So the seats in the saloon have two foam inserts, so once you have removed the first insert, there is a zip inside the cover so that you can remove the second. The back of the chairs were a little bit more tricky as they have a wooden panel, inside the cushion cover. A quick go with the screwdriver and they were soon off and in the washing machine. They really looked a lot brighter afterwards and was yet another job off the list

In Liverpool Sailing club, one of our members does personalised mugs, so I finally got around to making a set of six. We had gone through a lot of ideas but in the end we went very simple, with "I love Salty Lass" and "My Salty Lass loves me". They might be simple but they looked great.

Beverley, got the shortest straw in that she got the toilet. Ours was back flushing, which happens on the older pump versions of Jabsco toilets, sp we got a twist and lock. A little it trickier to use, but no back flushing so a job that was really good to get off the list

I got the job of cleaning out the lockers, so all the old ropes were removed and we spent a small fortune on new ropes.

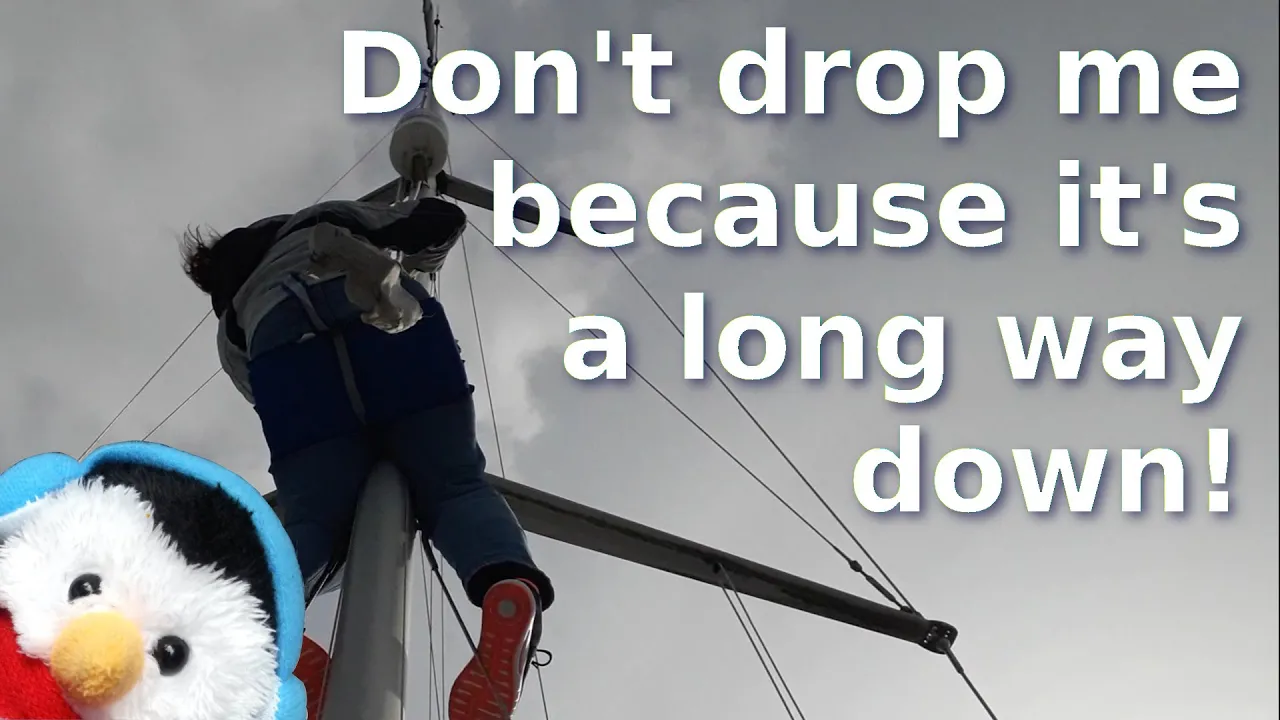

Beverley, then set to on checking the rigging. So every shackle was checked and all the standing rigging was checked. Beverley ran through the rigging first and she found loads of shackles that had not been ceased. In fact hardly any of the shackles at the bottom of the mast were done. Once she had gone over the boat, she showed me what I should be looking for so I went over the yacht and found one split pin that had lost a leg, so that was soon replaced. My favourite part of the task is rubbing my hand up and down the rigging and is a good reason to get rid of any plastic tubes on the rigging. They just discourage you from doing a job that should be done on a fairly regular basis.

Rigging mini guide

Choose a point on your yacht and go around the entire yacht checking everything. I like to start at the cockpit while Beverley started her checks in the video from the front.

- Bottle screws - Look at the split pins to see that each one has two legs and that they are bent back more than 45°

- Bottle screws - Look for cracks both laterally and longitudinal

- Swages - Make sure that they are even all the way down the line

- Deck fittings - Make sure that no cracks appear, especially at weld joints

- Shackles - Make sure that they are ceased

Knives -https://www.lakeland.co.uk/