We start preparing for going off grid, so that means buying equipment to construct a solar arch and the solar panels themselves. We also have to deal with a water leak from our hot water tank.

We were back in Liverpool, which meant unlimited access to great stuff like a washing machine and tumble dryer. For Prudence, it meant that it was a bad day as she got hand washed followed by a quick whirl around in the tumble dryer. She gets so irritated by the whole thing, she complains for days. We tell her not to get grubby then, but she loves sticking her beak into every thing.

The next day, the water pump kept on going on when there was no need for it to go on. So we turned off the water pump and had a quick look around to see what was up. It didn't take long to find that the bilges were full of water. A quick check on the type of water in there and it was clearly fresh water, not salt. So we turned on the bilge pump, which I am glad to report works and started to look for the source. To start with we looked in and around the water pump, but that seemed fine. So next Beverley started looking at all the pipes. When you live on a boat like we do, then the one thing that you need to be able to do is be a contortionist, because of all the small nooks and crannies that you have to get to. While she did that, I removed all our tins from out of the bilges and dried them along with the baskets that they live in. If you decide to store tins in your bilges like we do, then it is very important to remove labels. On one of the tins I had clearly forgotten to remove the label and it was just soaked. Another reason that you remove labels, is because insects lay eggs in the layer between the paper and the tin. Now we live in a cold climate, but we can always dream.

We eventually found the drip, it was by the hot water tank. The drip was quite slow, but when Beverley turned the water pump on, the drip increased quite significantly. So once the drip was found it was just a case of fixing it. That turned out to ne quite simple as we had to just trim the end of the pipe which had got brittle with age. Fitting the pressure fitting was a little bit more challenging, but Beverley got there in the end after much cursing and swearing. While she got all that done I took the opportunity to get our bilges all dry, then I polished our keel bolts, because I could.

One of the advantages of being in our home port was that we had a mailing address, although we used the marina office for all our deliveries in the end. We had discussed getting a solar arch made back in Peel, so seeing as we were going to be in Liverpool for a few days seeing family and friends, it was a good time to order up the stuff. When it arrived, it was nice and sunny, so we were able to sit out on the deck and open our boxes. It was like pass the parcel with all the layers of packing that our parcels had arrived in.

My box contained a huge array of shiny bits from Seascrew, they looked so shiny. No idea what they will look like in 10 years time but at the start of things they were beautifully shiny. Beverley's box contained a selection of goodies from Bimble Solar including a Victron charge controller, a long piece of cable and she also had another box which contained two flexible solar panels. We had gone for flexible panels as we were the ones that was going to install our solar panels and we wanted to be able to lift them over our heads. I have created a more detailed post with regard to all this called solar arch for a bavaria 36 which is on the lines of a how to, or in our case how not to, but if you can learn from our mistakes then that is a good thing as far as I am concerned.

We also had a load of pipe which Beverley messed about with, she is like that. When we were looking through the order, we realised that we were short three 1m lengths, so I checked what I had ordered and they had under sent, so I just got on the phone to Seascrew and they promised to send out the extra bits of pipe in the next order. Once all the bits were checked and sorted out, it was a real case of putting it all together. This meant, cutting the 1m lengths in two, so they made 50cm pipes and drilling holes in the deck. Never a popular move.

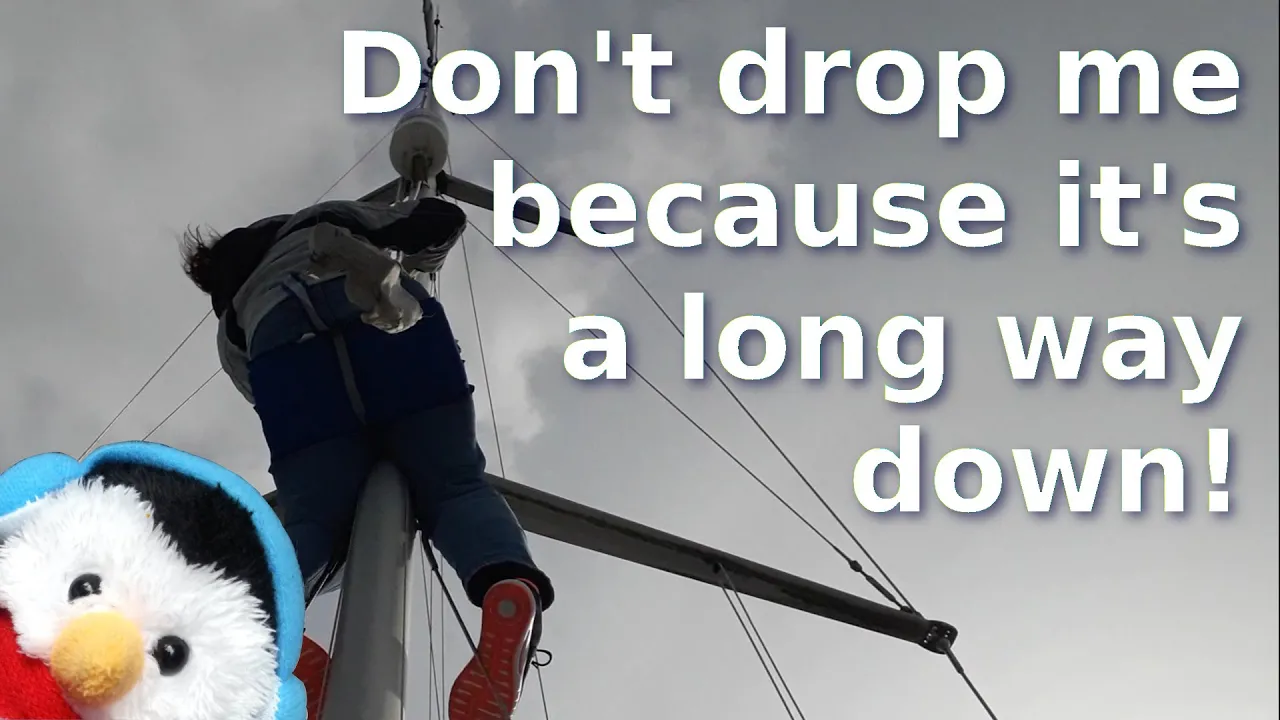

Once we had made the main part of the arch, Beverley created a cradle so that we could lift the arch onto the back. That was really good as it meant that our halyard was taking the strain rather than ourselves. It was raining the next day, so we went to the local DIY store to buy a wall. We wanted this particular wall as it was Light and UV stable. We would also need a spacer, but we hoped to make that out of the same stuff.

When we got back, the pipes had arrived so we cut those to length for our design. These seemed to be harder than the other set as they were too tough for the blades on our jigsaw, so we had to revert to the angle grinder. So that was all we did in Liverpool as we completed the work in Conwy. The post solar arch for a bavaria 36 covers all of the making of our solar arch, not just the bit we did in Liverpool.