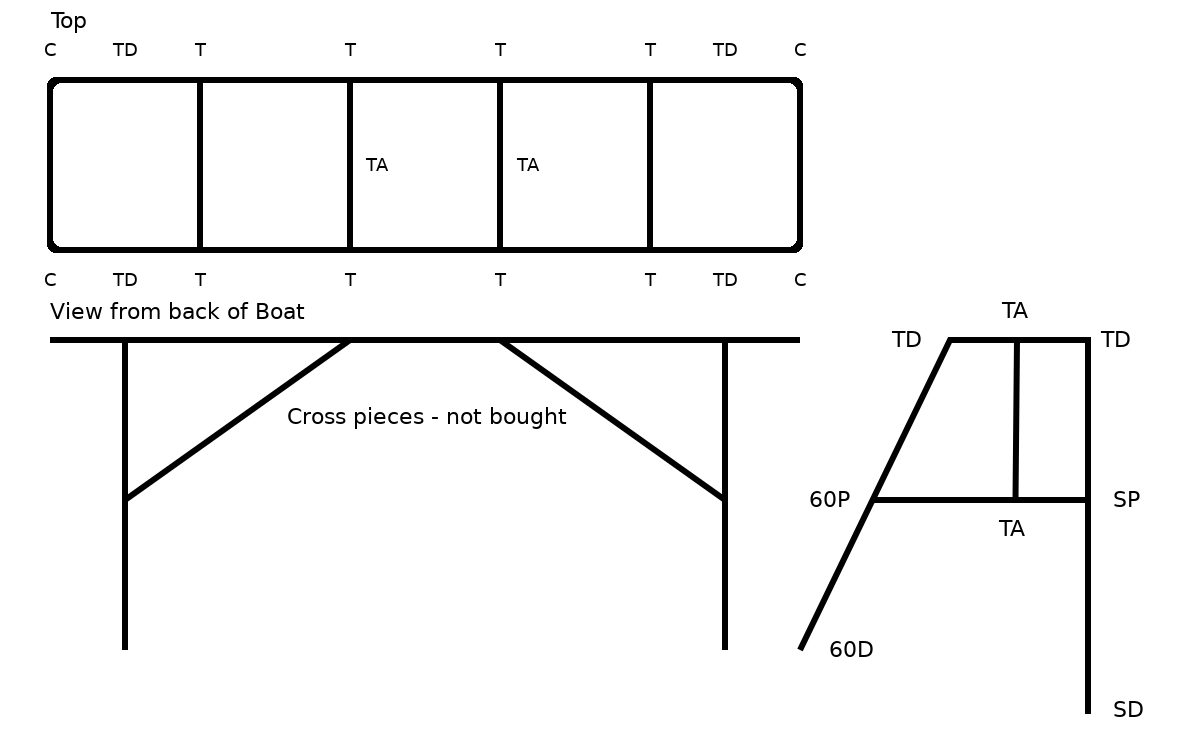

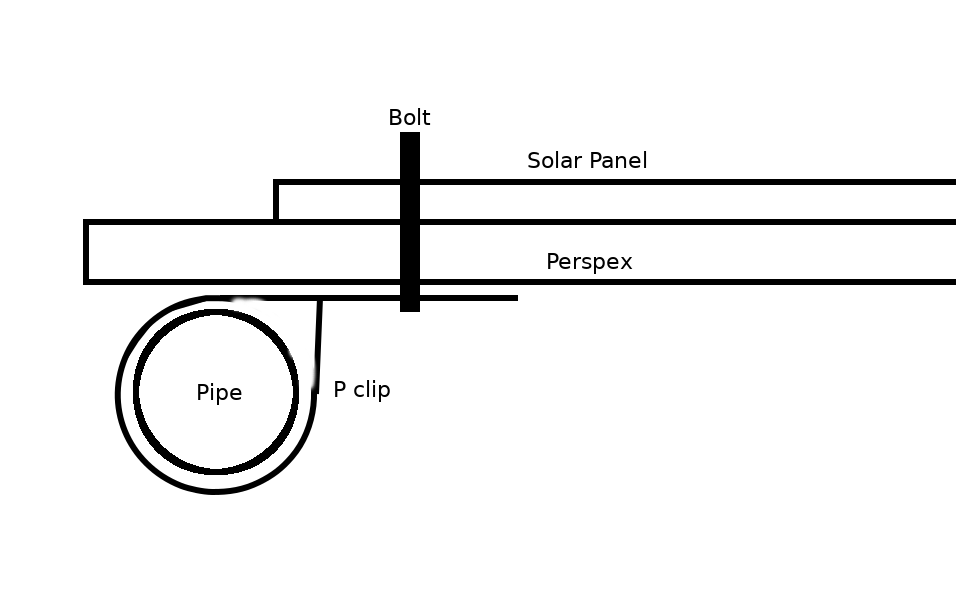

Equipment and contruction diagram for making a solar arch, plus ideas for improvements that you could use in your design.

There are lots of things to consider when creating a solar system for your Bavaria yacht, weight was one of our key factors, another was where we could mount the arch

Arch

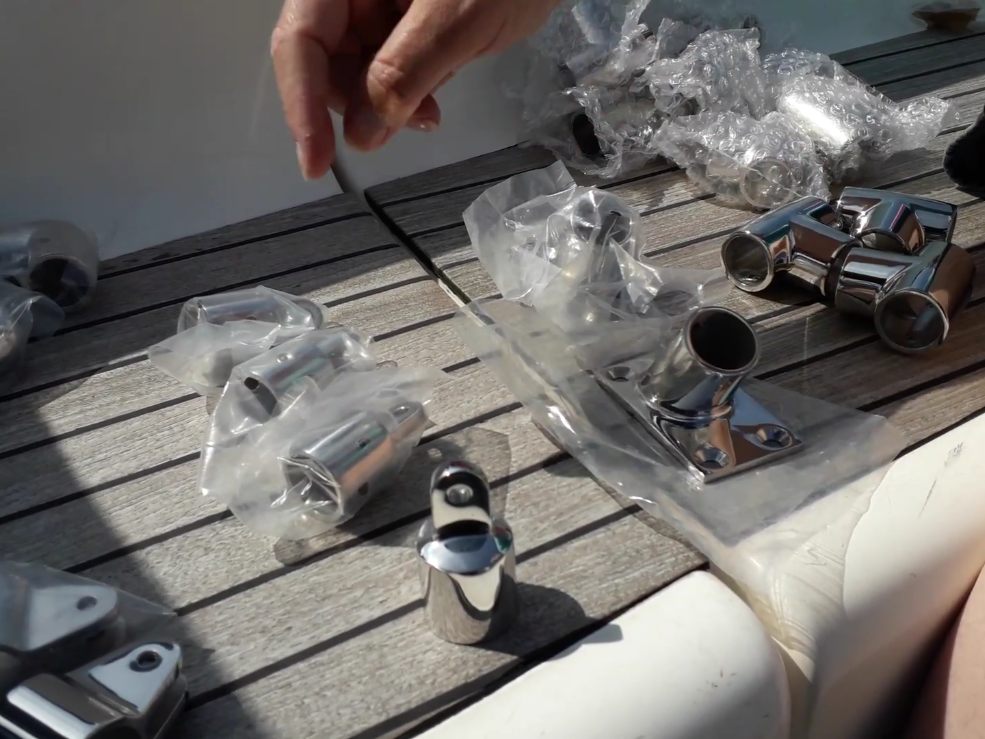

This we mounted on the back of the yacht using the hard point at the back and another fixing point on the rear of the boat. We used Seascrew to buy all the bits, and below is the list of all these items.